To say that drum brakes are outdated is a gross oversimplification. This system is indeed over a hundred years old, but contrary to expectations, it has not yet been sent to a technical museum. Moreover, "drums" continue to be installed on new cars, and many automakers do so.

At first glance, it may seem that the reason is trivial - economy. They say cheap cars are equipped with cheap brakes. However, this explanation does not stand up to scrutiny. Automakers know how to count money and understand perfectly well where you can save money, and where such "thrift" will result in recalls, reputational losses, and billions in costs. The situation with drum brakes is different: this is a conscious engineering choice.

The design of the brake drum with crescent-shaped pads has been used for decades and has been tested not only by time, but also by millions of kilometers of mileage. Yes, today they are almost never found on powerful and expensive cars, but in the segment of mass and budget models, "drums" feel quite confident. And this is despite the fact that they are noticeably more complex in design than disc brakes.

Why Drum Brakes Are So Tenacious

The main advantage of the drum scheme is resource and endurance. The contact area of the pads with the working surface of the drum is much larger than that of disc pads. This directly affects the system's ability to withstand load and effectively slow down the car.

Yes, drum brakes do not have a lightning-fast reaction. Their drive is designed so that actuation occurs slightly slower. But if they have already "taken hold", they do it thoroughly. It is not for nothing that in professional circles they are sometimes called "heavy caliber" - for their simplicity, power and ability to work stably with large masses.

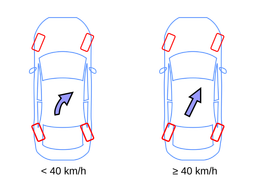

In a normal road situation, everything looks like this: with a slight press on the pedal, the front disc brakes are the first to come into operation. They take on the main load during everyday decelerations. If the driver continues to increase the effort, the rear drum brakes are gradually connected. And only in extreme modes do both systems work to the limit of their capabilities.

Heat, Dirt and Protection

Drum brakes also have another important advantage - thermal inertia. Heavy cast iron drums are able to accumulate and dissipate a significant amount of heat. This can play a decisive role during a long descent from a mountain or when driving fully loaded. Yes, some of the heat is transferred to the wheel disks, which can cause them to "seize" and the tires to overheat, but the brake mechanism itself remains operational.

The closed design is another plus. The drum is well protected from sand, dirt, snow and road salt. This is a serious advantage in poor road conditions and winter operation.

For comparison: one of the chronic problems of disc brakes is considered to be the jamming of the caliper piston. Even if the pad can be unjammed, such a caliper is often doomed to replacement due to uneven disc wear.

The drum system uses one cylinder with two pistons. The design is designed so that even if one of them is wedged, the second compensates for the force and allows both pads to participate in braking. In addition, the spring rings in the drive automatically select the gap as the pads wear, maintaining stable operation without constant adjustments.

The Price of Reliability - Complexity

However, all these advantages have a downside. The mechanism of drum brakes is noticeably more complex than disc brakes. Inside there are many springs, levers, latches and elements of automatic gap compensation. And this is what becomes the main source of problems.

Up to about 80-100 thousand kilometers with calm operation, "drums" usually do not cause trouble. But if the car often drives with overload, is actively used on the highway or in the mountains, the first signs of discontent may appear after 50 thousand kilometers.

This system requires attention. It is necessary to periodically clean the inner cavity of the drum from wear dust, check the condition of the pads, monitor and adjust the gaps. An error in maintenance leads to the fact that the pads begin to rub against the drum even when the pedal or handbrake is released. The result is that the car is pulled to the side, increased fuel consumption and accelerated wear.

Do not forget about the springs that fix the pads. Loss or incorrect installation of one of them leads to unpleasant rattling and unstable operation of the brakes even on a flat road.

Drum brakes are not a relic of the past, but a compromise engineering solution. They are reliable, durable, well protected from the environment and work confidently with loads. But you have to pay for this with the complexity of the design and the need for regular maintenance.

That is why "drums" are still alive: where maximum performance and sporty precision are not needed, they remain a practical and justified choice.