The Chinese electric vehicle market continues to actively invest in next-step technologies, and solid-state batteries are becoming one of the key areas. Sunwoda Electronic and Zhongwei New Materials have signed a strategic agreement to jointly develop materials and elements for all-solid-state batteries, including those for use in electric vehicles. The project involves the transition from laboratory development to pilot production and further industrialization.

According to published information, the cooperation covers several levels of the technological chain at once. We are talking about the creation of cathode precursors, cathode materials and the development of all-solid-state battery technologies. The financial parameters of the agreement are not disclosed, but the very format of the framework partnership indicates the long-term plans of the parties and the focus on scaling up production.

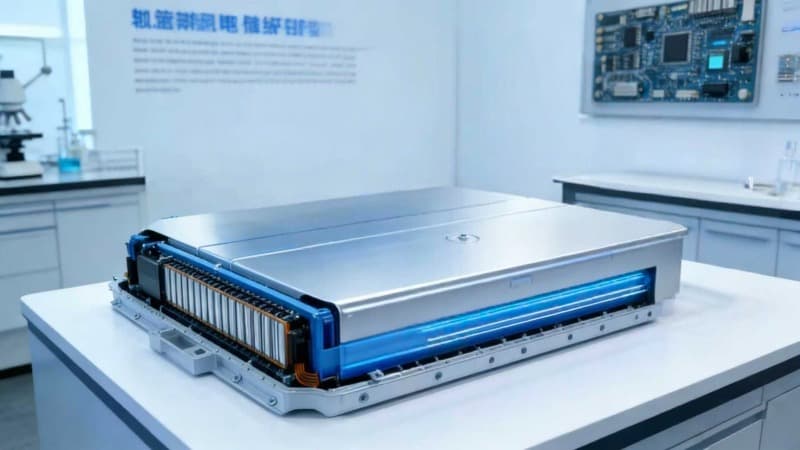

Sunwoda is well known as one of the largest Chinese manufacturers of batteries for consumer electronics, energy storage systems and the automotive sector. In the electric vehicle segment, it supplies lithium-ion cells and modules to such automotive giants as BYD, SAIC and GAC Group. It is the automotive division of Sunwoda Power Technology that will be a key participant in the new project, expanding the company's expertise in solid-state solutions.

Zhongwei, in turn, occupies a strong position in the market of materials for new energy sources. The company specializes in nickel- and cobalt-containing products, which are widely used in traction batteries. Its clients are already CATL, BYD and Farasis, and in recent years Zhongwei has been actively developing research in the field of solid electrolytes, striving to take a place in the future ecosystem of solid-state batteries.

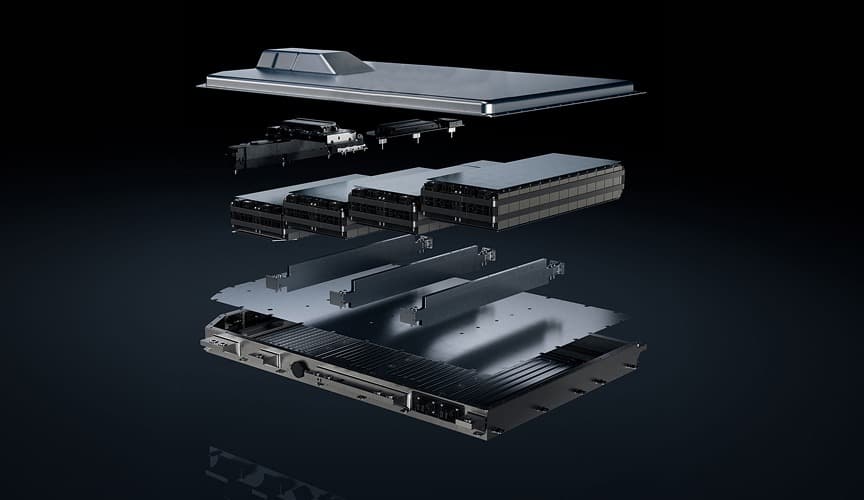

Sunwoda's technological base in this direction has already been laid. The company previously introduced a first-generation polymer-based solid-state battery with a specific energy of about 400 Wh/kg. 20 Ah prototypes withstood up to 1200 charge cycles at low external pressure, which is considered an important indicator for practical use. The next step will be the launch of a 0.2 GWh pilot line for the production of larger 60 Ah cells, focused specifically on electric vehicles.

The meaning of the Sunwoda and Zhongwei partnership lies in combining resources - from scientific development and engineering to supply chains and production facilities. This approach should reduce the time to market for solid-state batteries and reduce the risks associated with scaling complex technologies. For automakers, this means potential access to batteries with higher energy density, improved safety and increased life.

The project also fits into a broader industry trend. In 2025, several Chinese companies, including CATL, Funeng Technology and Qingtao Energy, have either already launched or are preparing pilot lines for the production of solid-state batteries. GAC previously announced the release of 60 Ah automotive cells using sulfide solid electrolytes. According to analysts, by 2030, global supplies of solid-state batteries could reach 614 GWh, and almost a third of this volume will be accounted for by all-solid-state solutions, which makes current investments strategically important for the future electric vehicle market.

Read also materials:

- AvtoVAZ officially explained which gasoline should be poured into Lada

- Moskvich announced prices for the Moskvich 6 sedan of the 2026 model year

- Tank raised prices for the entire model range in Russia: Tank 500, 700 and 400 have become more expensive

Now on home

The Russian car market consolidated its position at the end of January 2026

Simple selection and maintenance rules that really increase battery life

Development suspended due to budget constraints

Increased utilization fee and competition encourage companies to reconsider their presence in the domestic market

A high-precision gauge with an accuracy of 0.2 mm is installed on the line to control the quality of parts

Expert explained how to recognize a car restored after a serious accident

Company is exploring scenarios for launching a profitable production car

From oil starvation to carbon deposits: where is the truth, and where are the garage horror stories?

Which cars were the first to receive options that have become standard for comfort and safety

How changing ground clearance affects handling, lifespan, and legality of vehicle operation

Company Receives Approval to Start Production at Jaguar Land Rover Plants