In the lexicon of modern auto mechanics, there are two terms that, for many owners, sound almost like a diagnosis: "valve body" and "mechatronic unit." As soon as a mechanic in a service center utters one of these words, sums with five zeros instantly pop up in your head. Over the years, these components have acquired so many legends and horror stories that they have turned into symbols of something extremely complex, supposedly disposable, and extremely unreliable.

Hence the logical questions: are these different parts or the same thing under different names? What causes them to fail? And most importantly, can they be repaired, or is it always just about replacement?

Origin: Valve Body as an Analog Brain Made of Aluminum

To understand what a mechatronic unit is, you must first understand what its predecessor is: the valve body, also known as the valve plate. It was the "heart" and a kind of spinal cord of classic automatic transmissions for decades, starting back in the 1950s.

At its core, a valve body is a massive aluminum plate with an extremely complex labyrinth of channels milled inside. These channels house spring-loaded plunger valves, balls, and jets. Together, all of this forms a real hydraulic computing mechanism, almost completely without electronics.

The principle of operation is based on the pressure of the transmission fluid. The automatic transmission pump creates a flow of ATF, and the valve body distributes it throughout the system. Depending on the speed of the car, determined by the centrifugal governor, and the position of the gas pedal, transmitted by a cable, the plungers shift, blocking some channels and opening others. The oil is directed to the desired friction pack, compresses it - and the gear shifts.

It was pure, precise hydromechanics. Similar solutions were used in durable and resilient automatic transmissions such as ZF 4HP or Aisin A340. They were highly reliable but had limitations: shifts were not very fast, not always smooth, and could not adapt to the driver's driving style. Technological development required the next step.

Evolution: Mechatronic Unit as a Union of Hydraulics and Electronics

This step was the mechatronic unit. If the valve body can be compared to the spinal cord, which is responsible for basic reflexes, then the mechatronic unit is already a full-fledged brain, combined with the executive system.

From a constructive point of view, engineers took the classic valve body with its channels and valves and combined it with an electronic control unit. As a result, the mechatronic unit is a single module that includes a hydraulic part, an electronic board, solenoids, and sensors. Most often, this entire unit operates directly in the automatic transmission oil.

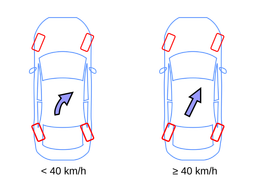

Now the plungers are controlled not by mechanical connections, but by solenoids - electromagnetic valves. The electronic unit of the gearbox collects data from many sources: vehicle speed, engine speed, gas pedal position, temperature, angle of inclination of the car. Based on this information, the ECU controls the solenoids with high accuracy, directing ATF flows exactly where they are needed at the moment.

This approach gave noticeable advantages. Gear changes in modern gearboxes like DSG or PDK began to take fractions of a second. The pressure is regulated so smoothly that the change of gears is almost not felt. The gearbox adapts to the driving style of a particular driver and keeps the engine in the most efficient rev range, increasing fuel efficiency.

Causes of Failures: What Goes Wrong

Against the background of all this technological elegance, the question naturally arises - why do such components still break down? There are several main reasons here.

The first and most dangerous is contaminated oil. Wear products of friction linings turn ATF into a fine abrasive mixture. This dirt damages the precision surfaces of plungers and channels, provoking their sticking. Solenoids, working with minimal clearances, also suffer from contamination and begin to function incorrectly.

The second enemy is overheating. The normal operating temperature of modern automatic transmissions is in the range of 90-100 °C, but in dense city traffic jams it easily rises to 110-120 °C. At such values, the oil quickly loses its properties, and electronic components actually operate in a mode of constant thermal stress. Control boards, sensors, and wiring are literally "cooked" in a hot environment, which causes cracks in the soldering and premature failure of solenoids.

Finally, natural wear and tear cannot be ruled out. Solenoids are electromechanical elements that continuously open and close. After 150-200 thousand kilometers, they simply exhaust their resource. Similarly, the plungers of the valve body wear out - pressure leaks occur over time.

Repair or Replacement: What Practice Shows

The main question for the owner is whether all this can be restored.

The classic valve body in most cases can be repaired. It is dismantled, completely disassembled, washed in an ultrasonic bath, the condition of the plungers and channels is checked, repair elements are installed if necessary, and gaskets are replaced. The procedure is laborious, but quite feasible.

The situation with the mechatronic unit is more complicated. The hydraulic part is repaired according to the same principles as a conventional valve body. Solenoids can be tested on a stand and faulty ones can be replaced - this is the most common scenario. But the electronic board remains the most vulnerable place. If the problem is a cracked solder joint, an experienced specialist can restore it. If the processor is damaged or the firmware is lost, it is most often a matter of replacing the board or the entire unit as a whole.

The bottom line here is simple: the valve body is a purely hydraulic "nervous system" of the gearbox, and the mechatronic unit is the same valve body, supplemented by an electronic "brain." Both components suffer primarily from dirty and overheated oil. Their repair is possible, but requires high qualification and accurate diagnostics. And no matter how trite it may sound, the best strategy remains prevention: timely oil changes and control of the cooling system allow these complex mechanisms to work for a long time and without dramatic consequences.