In the popular mind, it is the "Gazelle" that is considered the car that pulled the Gorky Automobile Plant out of a difficult financial situation in the 90s. This is partly true, but more utilitarian versions made a real contribution to the survival of the enterprise — the GAZ-3302 truck and the van based on it. However, the management of GAZ quickly realized that the passenger transportation segment could be even more profitable, especially if they offered the market something more compact.

The peak in demand for passenger "Gazelles" occurred in 1995–1996, after which customers began to increasingly inquire about shortened versions. Many were looking for a minibus not for route work, but as a service or family transport for 5–6 seats. An important condition was the registration of the car as a passenger car, and not a bus or commercial van.

Marketers and the sales department saw the problem clearly: one, even very successful model, could not hold the market. In addition, the demand structure was changing — private traders played an increasing role, for whom the "Gazelle" often turned out to be too large and heavy. The complaints were typical: it doesn't fit in the garage, it drives half-empty, fuel consumption is higher than expected.

Such buyers often ended up choosing more compact Korean or French vans. Realizing the risk of losing customers, GAZ showed prototypes of a shortened version of the "Gazelle" as early as 1996. The wheelbase was reduced by 140 mm, the overhangs by almost half a meter, as a result, the car became shorter by 660 mm, received a gross weight of 2.8 tons and a carrying capacity of 700 kg.

However, even such parameters were considered excessive by the market. Buyers wrote to the factory, offering dimensions of no more than 4.5 m in length, up to 2 m in height and about 1.9 m in width — in fact, within the limits of a D-class passenger car. It was proposed to limit the carrying capacity to 500 kg, focusing on efficiency and lower weight.

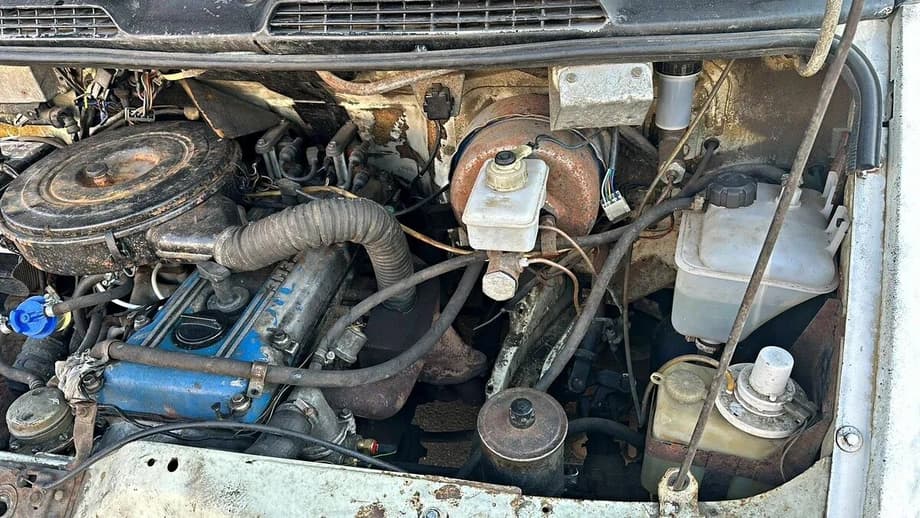

The plant had its own limitations. There were no funds to develop a completely new model. Despite the use of up to 80% of the Gazelle's units, the Sobol's body required separate tooling. A set of stamps and press equipment cost about $76 million, and the default only worsened the financial situation. At the same time, both cargo and passenger versions were planned.

In 1999, the Sobol-Barguzin GAZ-2217 appeared with a lowered roof and more comfortable chassis settings — in fact, the very minivan that buyers of the mid-90s dreamed of. Later, a flatbed version with a carrying capacity of 800 kg was released, the demand for which grew slowly but steadily, and by 2006 production became conveyorized.

Experiments continued: the all-wheel drive GAZ-23107 tried to win back part of the market from UAZs, and the version with ten seats remained experimental. Today it is obvious that the launch of the Sobol based on the Gazelle was a compromise of its time — forced, but timely, allowing GAZ to occupy a niche that might otherwise have remained with imports.