A modern car's braking system is a complex and high-tech system that directly affects road safety. Over the millennia, engineers have gone from primitive wooden pads to electronic systems with intelligent control. Today, brakes are no longer just a stopping mechanism, but a full-fledged element of active safety, closely linked to the car's electronics and software.

According to industry estimates, the introduction of innovations in braking systems reduces accidents by approximately 40%. However, technological development always requires a reasonable balance between efficiency, reliability and cost. At the same time, even the most advanced solutions do not negate the basic principles: the quality of materials and regular maintenance remain key factors in the reliable operation of brakes. Ignoring prevention is especially dangerous in conditions of high speeds and dense urban traffic.

A long path of development: from antiquity to the beginning of the automotive industry

The history of braking systems goes back thousands of years. Back in the era of the Roman Empire, chariots were slowed down with the help of corrugated shoes, which were pressed against the wheels with special levers. In the 19th century, wooden pads covered with leather were installed on the front axle of horse-drawn carriages.

The first cars inherited mechanical brakes. On Karl Benz's early cars, such systems wore out after only 1-2 thousand kilometers of mileage, which by modern standards looks like an extremely modest resource.

The emergence of discs and drums

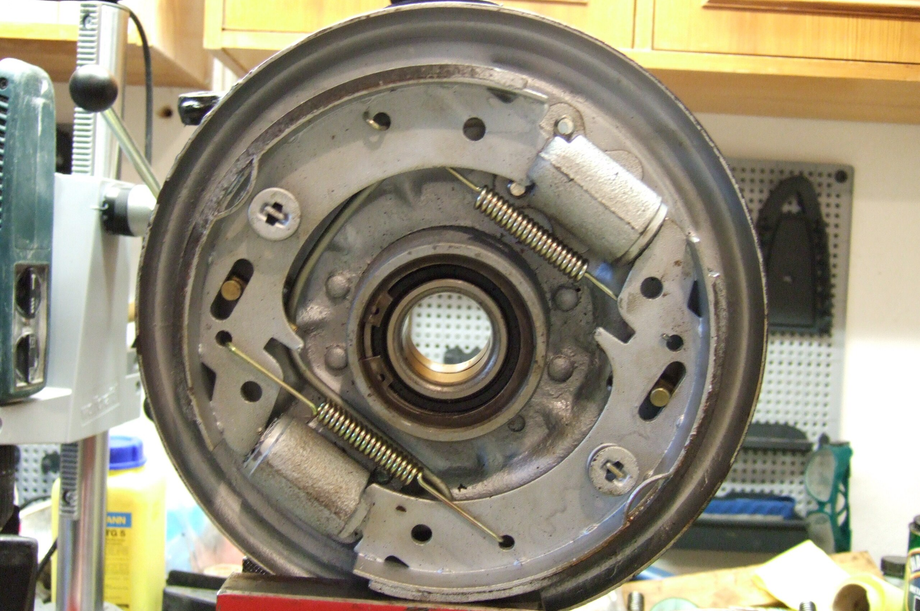

In 1902, the first disc brake with copper pads was patented. However, due to noise and low comfort, it was inferior to more practical solutions. In the same year, internal drum brakes appeared, which quickly became an industry standard. The use of asbestos linings made it possible to increase the service life of parts up to 5-10 thousand kilometers, which at that time was a serious breakthrough.

Further development followed the path of increasing efficiency and reliability. In 1921, a hydraulic drive appeared, later - vacuum boosters (1928). In the 1940s, aluminum drums with cast iron inserts began to be used, in the 1960s - dual-circuit systems, and in 1971 the anti-lock braking system ABS was introduced.

A separate milestone was the use of disc brakes in motorsport. In 1952, they largely ensured the success of the Jaguar XK120 at the 24 Hours of Le Mans race. Over time, such solutions became not only effective, but also affordable, and by the 1990s, disc brakes had almost completely replaced drum brakes on mass-produced models. The latter remained mainly on budget cars.

Modern braking systems

Today, braking systems are divided into service, parking and emergency. A number of models, mainly trucks and buses, also use a duplicate system designed to maintain handling and reduce the load on the main one.

The most common type remains disc brakes. In them, pads are pressed against a metal disc using calipers with one or more pistons. Such systems are effectively cooled, capable of self-cleaning and operate stably in a variety of conditions.

Drum brakes are better protected from dirt and external influences, but are less effective at high speeds and prone to overheating. At the same time, they are approximately 30% cheaper than disc brakes, which explains their preservation in the budget segment.

By type of drive, most passenger cars use a hydraulic system. Heavy vehicles more often use a pneumatic drive, and hybrids and electric vehicles use electric and combined solutions. Electronic braking control systems have become a de facto standard: ABS, ESP and EBD are installed on approximately 95% of all new cars.

Materials: from asbestos to composites and ceramics

Over the past decades, the materials of brake components have also changed significantly. Asbestos, which is hazardous to health and the environment, has been replaced by modern friction materials and composites with metal inclusions. Ceramics, rubber and graphite are also widely used.

The most common material for brake discs remains cast iron. More expensive cars use aluminum alloys with cast iron inserts, and premium and sports models are equipped with ceramic and carbon-ceramic brakes. Such systems can withstand extreme temperatures, last up to 300 thousand kilometers and remain effective even at very high speeds.

What awaits brakes in the future

In the coming years, a wider distribution of electronic braking systems without a mechanical connection between the pedal and the actuators is expected. Similar solutions are already used in electric vehicles and allow you to effectively integrate energy recuperation.

After 2035, the appearance of fully electric brakes with intelligent control is predicted. Such systems will be able to analyze the road situation and prepare the mechanism for braking in advance. It is assumed that brake fluid will be abandoned in favor of ball screw mechanisms and the use of new composite materials with nanoparticles.

These technologies can significantly increase the level of safety, but at the same time will increase the car's dependence on electronics and create new risks associated with cybersecurity and vulnerability to hacking.

The evolution of braking systems continues, and from a simple mechanical unit they are increasingly turning into an intelligent complex, on which not only comfort, but also the life of the driver and passengers directly depends.