Adaptation is a term that many people have heard, but not everyone clearly understands what this word means. For some, it is a miraculous remedy for any jolts, for others it is another marketing ploy, and some do not even imagine what it is about. Let's try to understand the essence of the process.

Modern ATFs are not a primitive set of gears. We are dealing with complex technical organs with their own logic of operation. Their electronic control unit is capable of learning, and it is this continuous process that is called adaptation.

But what is behind this word? A miracle that will "cure" jerks? Or a fashionable term that helps justify expensive procedures? I want to understand how the gearbox corrects its behavior, why "kicks" appear over time, and what "adaptation reset" really is: a salvation or a dummy.

Chapter 1. Why does an automatic transmission need "learning"?

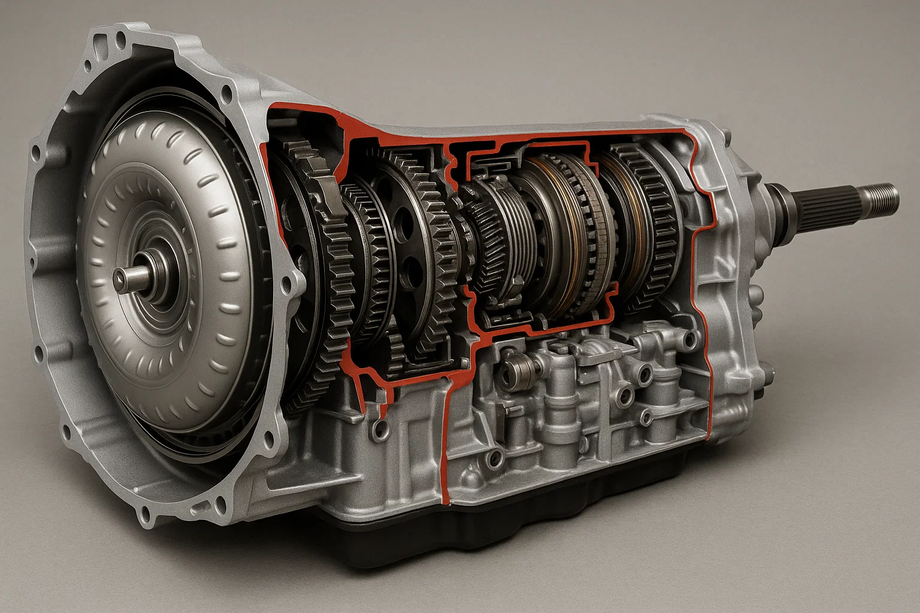

Imagine an ideal unit that has just left the assembly line. All clearances are verified to the nearest hundredth, the pressure in the hydraulic system is exemplary, and the friction clutches are fresh. Engineers have pre-programmed the Electronic Control Unit (ECU) with switching schemes: with such pressure on the gas pedal and such revolutions, send a strictly defined signal to a specific solenoid so that the switching takes place in the standard 0.3 seconds.

However, in real operation, everything is different.

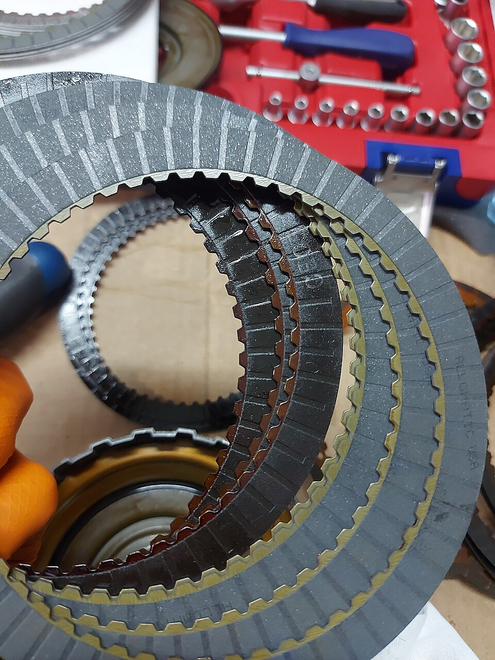

- Mechanics wear out: friction clutches wear out, clearances increase, springs in the valve body lose stiffness.

- Oil ages: ATF thickens or, conversely, thins out from heating, changing viscosity.

- Pressure drops: the pump eventually delivers a smaller volume.

If the gearbox continued to operate exclusively according to factory tables, then as wear increased, the shifts would inevitably become worse. Let's say the clearance has increased - the friction clutches will close more slowly, and the driver will feel a dip or delay. And if the solenoid is sticking, the pressure will rise too sharply - hence the impact.

It is precisely to compensate for such changes that adaptation exists.

Chapter 2. How the gearbox "thinks": the learning mechanism

Adaptation is a process of constant self-correction. The electronic control unit always analyzes what is happening inside the transmission. The main assistants are sensors that monitor the speed of rotation of the input and output shafts.

If you explain it in simple words:

- Command. The ECU initiates a shift, for example, from 2nd to 3rd gear, and relies on factory data: under such conditions, it should take about 300 milliseconds.

- Control. The electronics monitor the change in shaft speeds: one slows down, the other accelerates.

- Analysis. The process is completed, and the unit compares the actual time with the calculated time. Let's say that instead of 300, it turned out to be 450 milliseconds - the delay is obvious.

- Correction. The ECU records the conclusion: "In such conditions, it is worth increasing the pressure or activating the solenoid a little earlier." It saves the new adjustments in memory.

This happens daily, on every shift - up and down. The gearbox regulates hundreds of parameters: the filling time of the packages, the pressure in the channels, the moment the valves are triggered. All this is in order to keep the shifts as close as possible to the standard.

Adaptation to driving style

In addition, the gearbox monitors the driving style. If the driver accelerates actively, the unit understands: you need to hold the gears longer, and switch - faster and harder. If the car spends its life in traffic jams, the algorithm will become softer and will strive for an early transition to higher gears.

Chapter 3. When adaptation no longer saves: causes of "kicks"

Sometimes you can hear the phrase: "The gearbox is used to being bad and therefore kicks." This is not an accurate statement. The ATF does not strive for jerks - it tries with all its might to smooth out the consequences of wear. And a kick is already a signal that it is no longer possible to compensate for the changes.

Why is this happening?

The wear of the friction clutch or solenoid can go so far that even the maximum ECU adjustments do not give a result. The unit applies the maximum possible pressure, but the clearance is selected too slowly. Or, conversely, the solenoid reacts with a jerk. It is at this moment that an impact occurs during switching.

Adaptation does not repair mechanical problems - it only masks them. And this is the main risk when buying a used car: the gearbox may work smoothly only because the ECU is compensating for worn-out iron with its last strength. But it is worth resetting the adaptations or replacing the oil - and hidden defects will immediately appear. Therefore, buying a car with an ATF without a full diagnosis, including an analysis of adaptation values, is a pure lottery.

Chapter 4. Resetting adaptations: reboot or setup?

Now - to the most discussed. Many services offer to "reset adaptations". What does this mean?

In fact, you are zeroing out all the accumulated ECU statistics. The gearbox "forgets" its corrections and returns to the factory parameters.

When is it useful?

- after repair: replacing the valve body, solenoids, friction clutches or oil - the gearbox needs to "understand" that it is working with new parts;

- when changing owners: so that the algorithms adapt to a different style;

- after an oil change: so that adaptation starts again, taking into account the new viscosity.

When is it harmful?

If the jolts are caused by mechanical wear, resetting the adaptations turns into a trap. The gearbox, which barely maintained smoothness, will return to the factory settings and start working abruptly - sometimes so much that it becomes impossible to drive. This is not treatment, but turning off "pain relief".

How is the reset performed?

The procedure is elementary: either use the standard algorithm, or connect via a program on the phone with a simple ELM327 adapter.

Adaptation is a brilliant mechanism that allows the ATF to maintain confidence and smooth operation for many years, compensating for changes in the characteristics of the units. But this is not a miracle cure. If the gearbox has started to "kick", you should not immediately erase its memory - first you need a qualified diagnosis to find out what exactly is forcing the "brains" to rebuild the work to the limit.