The modern automotive market is changing so rapidly that even familiar car parts are gaining new functions. A prime example is RunFlat tires, which in recent years have transformed from a niche technology into a mass-market solution, especially among premium brands. The ability to continue driving after a puncture seems almost ideal: no roadside tire changes and no unnecessary stress. But is RunFlat truly a universal choice, or does this technology have hidden pitfalls?

To understand, it's important to know how these tires work, what types exist, and what limitations the owner faces.

What is RunFlat and how does it work?

The designation Run On Flat (or RunFlat for short) on the tire sidewall means that the tire can temporarily maintain operability even at zero pressure. This is not a marketing gimmick, but an engineering solution designed for emergency situations - when it's important to get to a service station without panic.

However, RunFlat is not a replacement for a full-fledged wheel. Manufacturers immediately emphasize that prolonged operation without pressure is unacceptable. It's an insurance policy, not a constant driving mode.

The technology has evolved gradually. At various times, engineers have tried supporting rings, special inserts, and self-sealing compounds. However, the reinforced sidewall scheme has become the mass standard. These are the tires that are now installed on BMW, Lexus, Infiniti, Mercedes-Benz, and other models in the mid- and premium segments.

How RunFlat differs from regular tires

At first glance, a RunFlat looks like a regular tire, but structurally it is noticeably more complex.

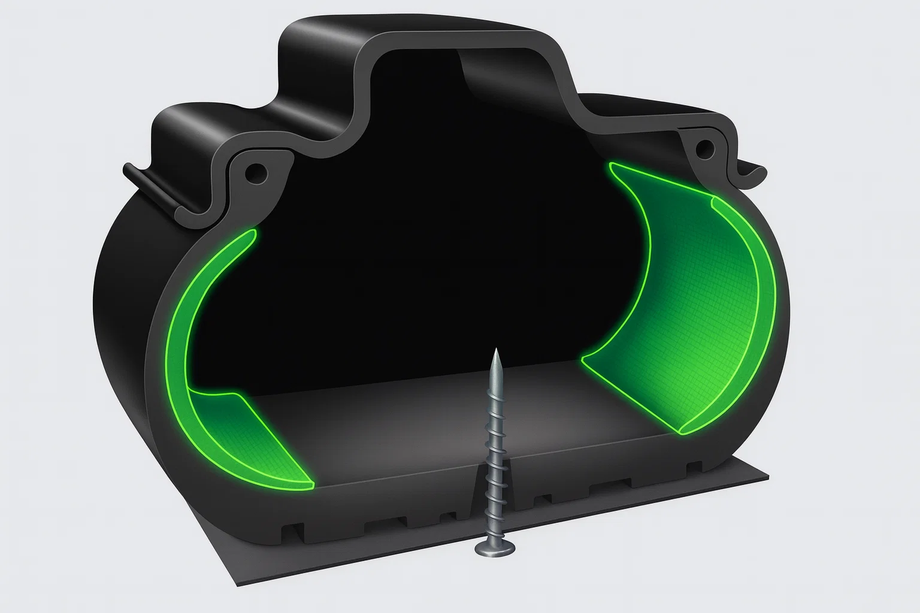

- Reinforced sidewall The main difference. In a standard tire, the sidewalls collapse when pressure is lost, the rim starts to cut the rubber, and the tire quickly deteriorates. RunFlat retains its shape: the profile sags slightly, but the rim does not contact the road.

- Strong cord The carcass is reinforced with additional layers and metal threads, which increases rigidity and resistance to loads.

- Different bead area The bead geometry is designed to hold the tire on the rim even under severe deformation.

- Heat-resistant compound When driving without pressure, the load and heat fall on the sidewall. Therefore, RunFlat uses special compounds that are resistant to overheating.

As a result, the tire is much stiffer than a regular one. This is both its key advantage and its main disadvantage.

RunFlat markings for different brands

Although the principle of operation is the same, manufacturers use their own designations:

- Goodyear - Run On Flat, EMT

- Kumho - XRP

- Nokian - FRT

- Yokohama - ZPS

- Continental - SSR

- Michelin - ZP

- Dunlop - DSST

- Bridgestone - RFT

- Toyo - TFR

When buying, it is important to consider the marking, not just the appearance of the tire.

RunFlat varieties: not everything is so clear-cut

In addition to classic tires with reinforced sidewalls, there are solutions that are often mistakenly called RunFlat.

- Supporting ring A rigid ring is installed on the rim, on which the tire rests when pressure is lost. The design is reliable, but heavy and expensive. It is mainly used on special equipment.

- Seal Inside The inner layer is covered with a polymer that seals punctures up to 5 mm. This tire holds pressure, but does not allow you to drive completely deflated, so it does not belong to real RunFlats.

Pros of RunFlat: when the technology is justified

The main advantage is the ability to continue driving after a puncture.

Average parameters:

- speed - up to 80 km/h;

- range - from 50 to 150 km.

In real conditions, this can play a decisive role - especially on the highway, in the dark, or in bad weather.

Additional advantages:

- no need to carry a spare tire;

- more space in the trunk;

- more predictable vehicle behavior in the event of a sudden tire rupture.

Cons of RunFlat: what is important to know in advance

The technology also has enough disadvantages.

- Increased weight It increases the load on the suspension and may slightly increase fuel consumption.

- Stiffness and reduced comfort The ride becomes less smooth, noise increases, and grip properties may be inferior to classic tires.

- Maintenance difficulties Not every tire shop works with RunFlat - special equipment is required.

- Mandatory TPMS system Without pressure sensors, the driver may not notice a puncture and damage the tire completely.

- Poor repairability In many cases, after driving without pressure, it is easier to replace the tire than to repair it.

- High price The overpayment compared to regular tires reaches 15-50%.

Experts' opinion on RunFlat safety

Experts emphasize that the operation of RunFlat without pressure is strictly limited. When the car is fully loaded, the permissible mileage is about 50 km, when driving alone - up to 150 km. The maximum speed is 80 km/h, and in rain or snow - no more than 50 km/h.

In addition, after a puncture, the sidewalls often receive hidden damage that cannot be visually detected. That is why manufacturers do not recommend repairing such tires.

Also, without a pressure monitoring system, the use of RunFlat loses its meaning - the driver may simply not notice the moment of the puncture.

Is it worth choosing RunFlat?

RunFlat is a modern engineering solution created for the safety and peace of mind of the driver. These tires really help to avoid many problems in a critical situation.

However, they cannot be called a universal option:

- yes, they allow you to drive after a puncture;

- yes, they increase safety;

- but they require high costs and compromises in comfort.

RunFlat is perfect for those who drive a lot on highways and appreciate the opportunity not to stop at an inconvenient moment. For those who put ride smoothness and ease of maintenance first, it is more reasonable to consider classic tires or technologies like Seal Inside.

RunFlat is not a panacea, but a powerful tool that can play a decisive role at the right moment.